Name

Batch identification

Description

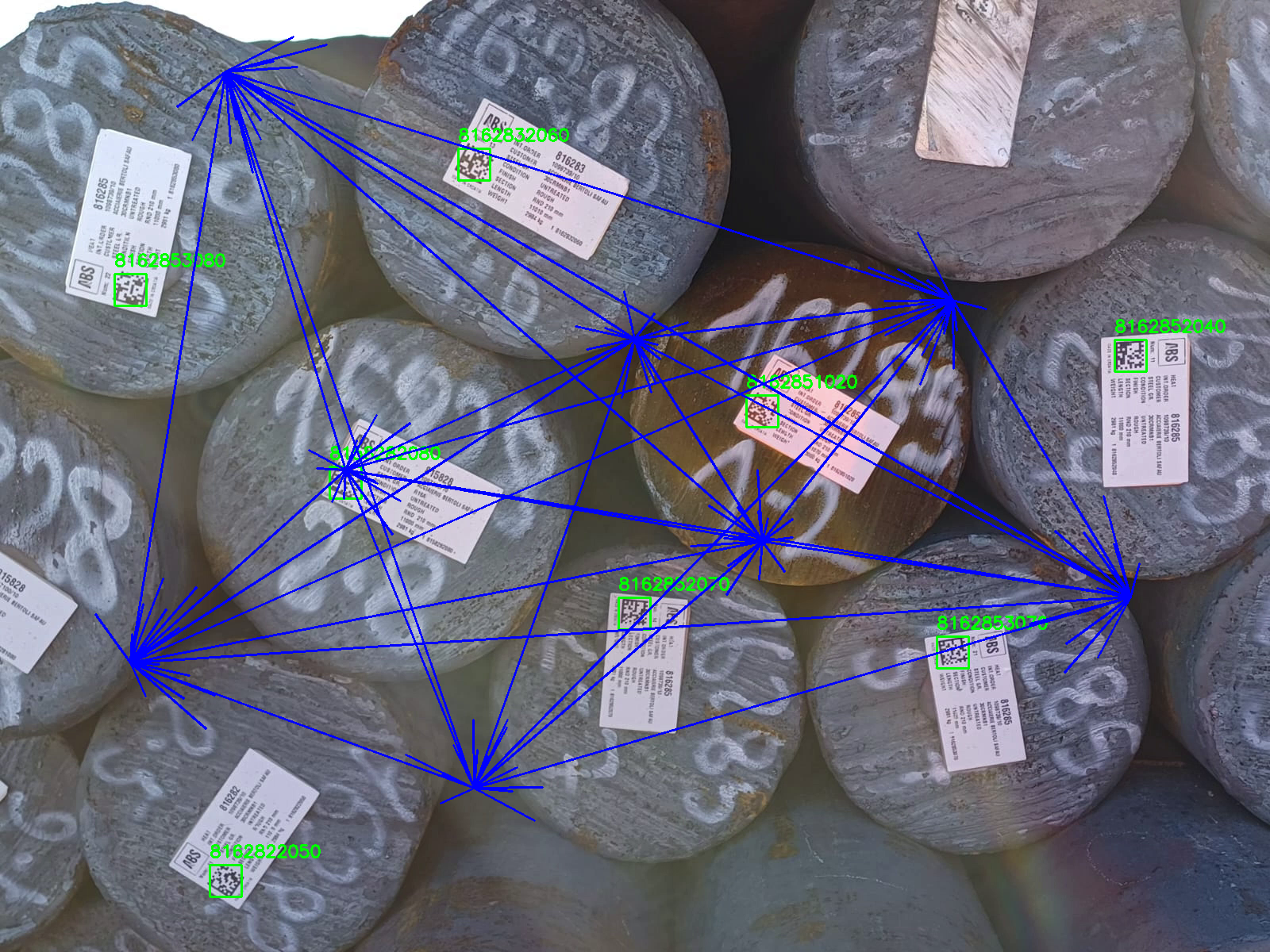

This tool is developed to automatically identify the batch code associated with stacked materials—such as steel bars—in the ABS Pilot. The batch code is a critical identifier used for tracking, traceability, and quality assurance within the industrial workflow.

The system processes image data captured from cameras positioned above or near the material stacks. It detects and extracts the batch code, which may be printed, tagged, or embedded via QR/2D codes. The detection pipeline is designed to achieve at least 90% successful identification under realistic conditions, including variable lighting, partial occlusion, and material placement inconsistencies.

By automating batch identification, the system reduces the need for manual input, lowers the risk of data entry errors, and ensures that materials are correctly logged and traced throughout the production and logistics process. This functionality plays a key role in maintaining end-to-end visibility and compliance in the ABS Pilot scenario.

Type

Tool

Layer

DTR

HRL

4.1.3

Partners

NORCE, MI

Pilot

Pilot 4 - ABS